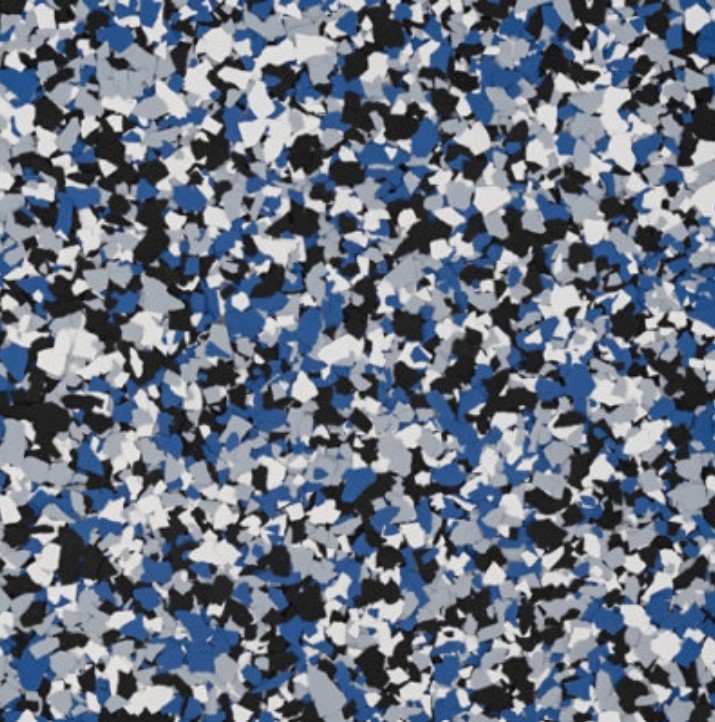

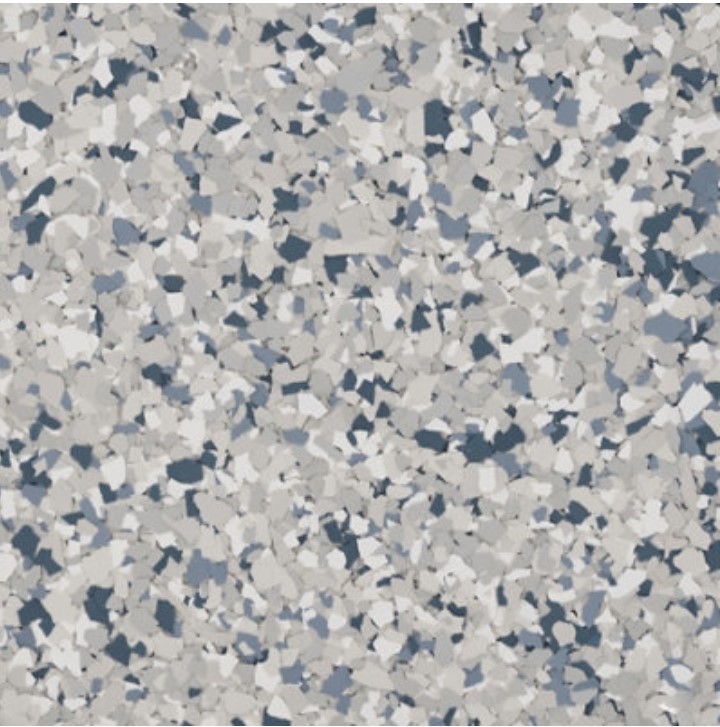

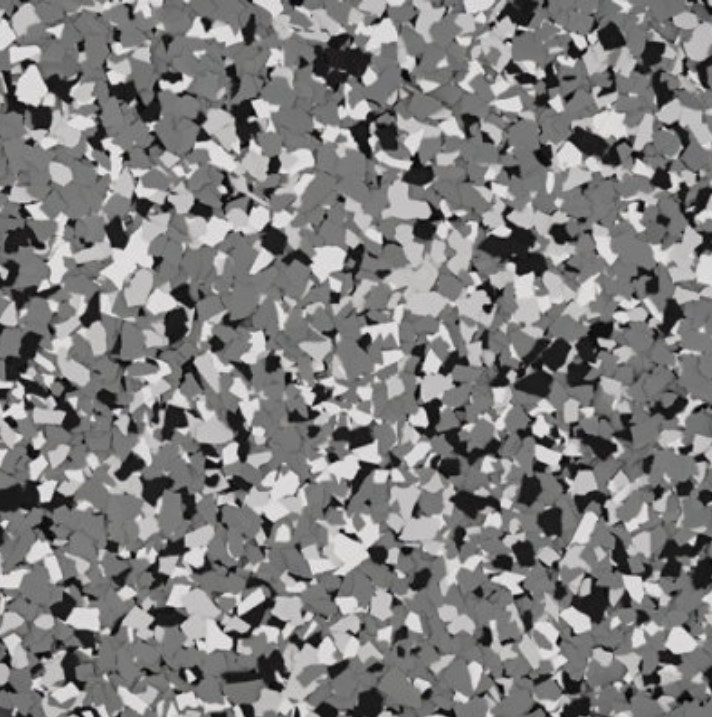

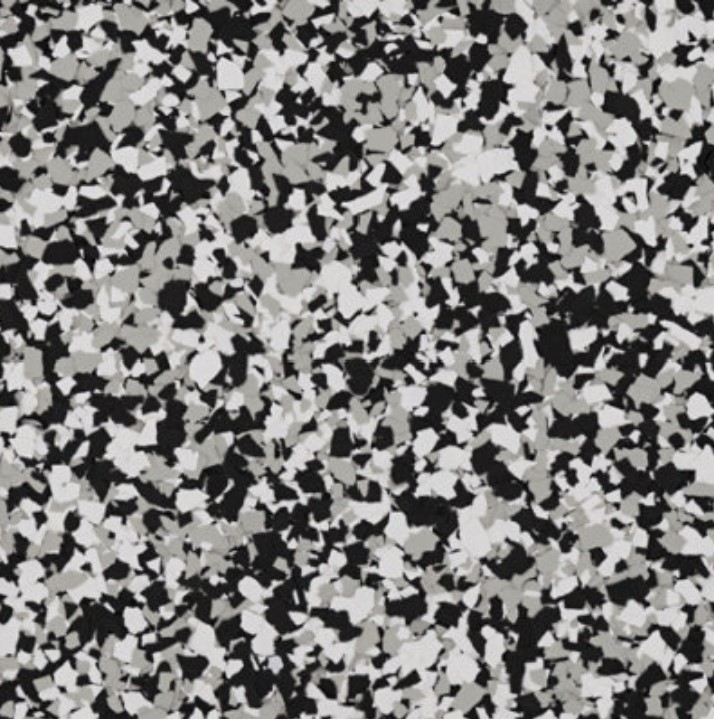

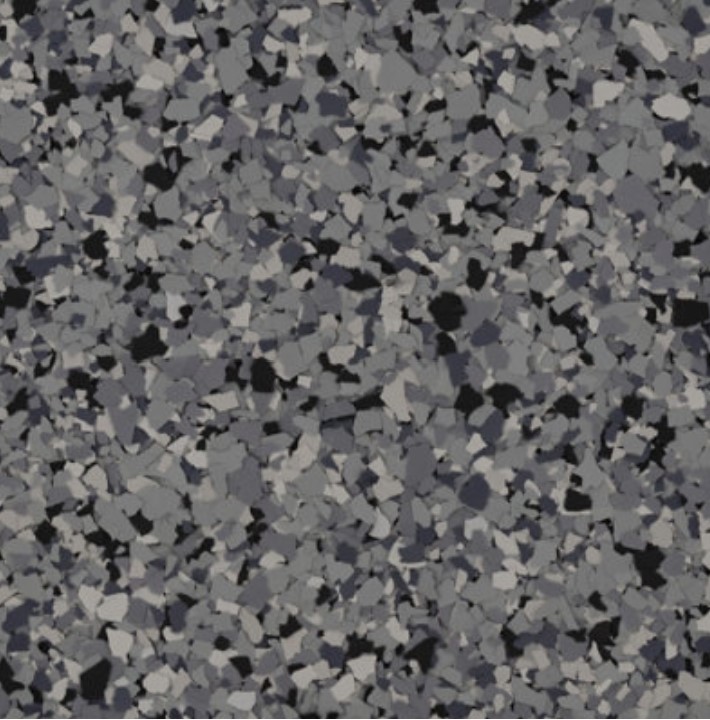

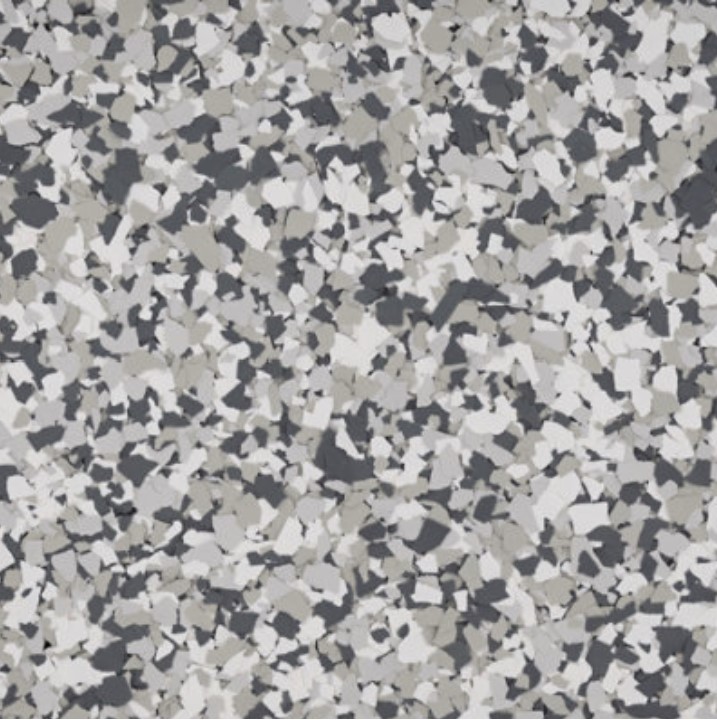

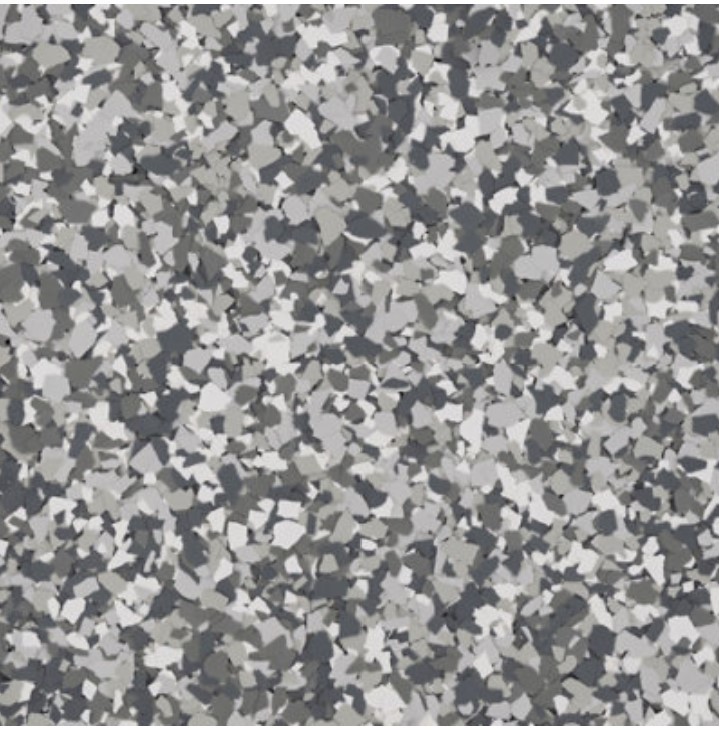

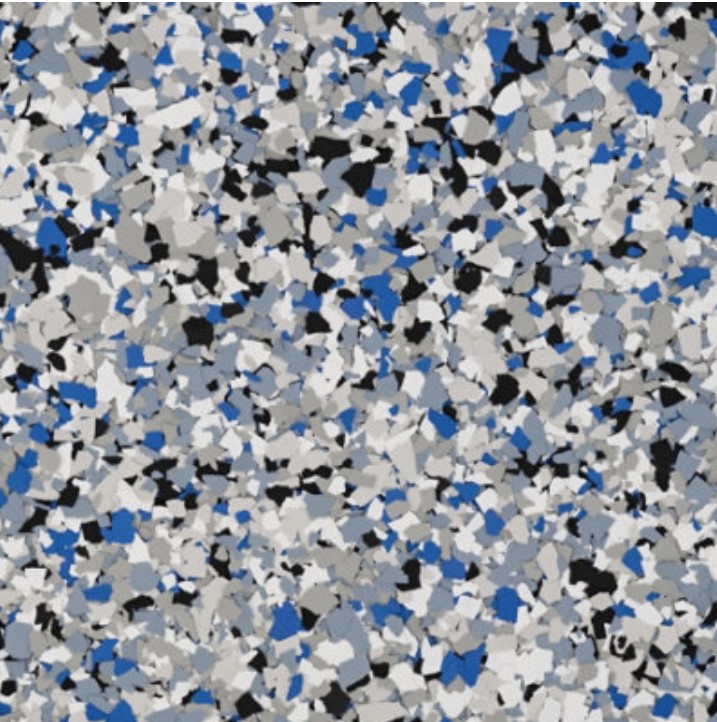

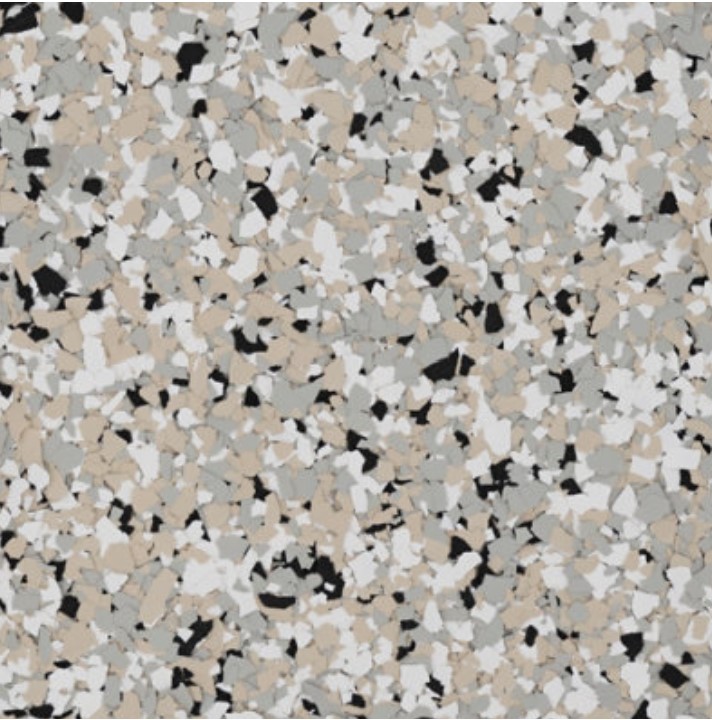

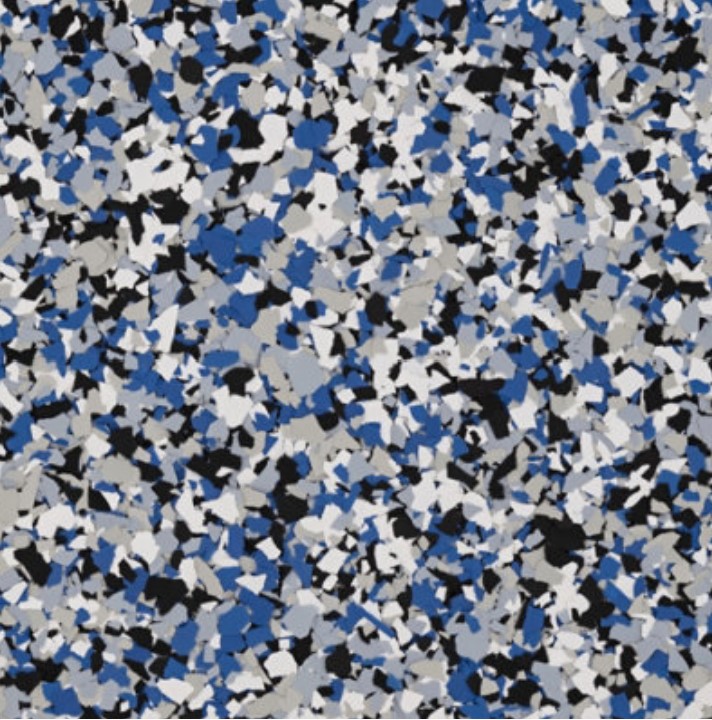

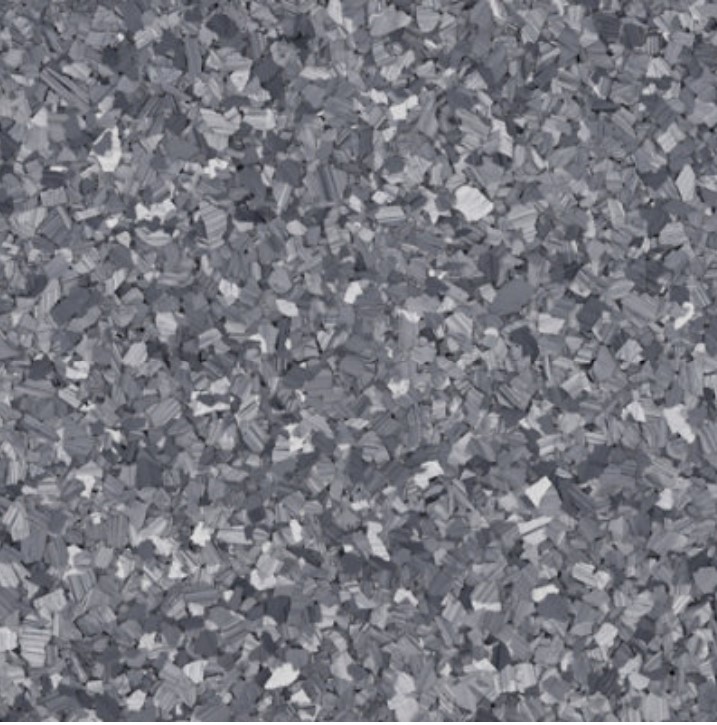

Full Flake is also known as faux granite. The flake medium is broadcast into epoxy. The flakes or “chips” come in an assortment of sizes 1/16, 1/8 and 1/4 are most popular.

SCROLL DOWN FOR STANDARD COLORS

OR CREATE A CUSTOM COLOR HERE: Design Tool for Custom Colors

TORGINOL FLAKE COLOR CHART & BROCHURE

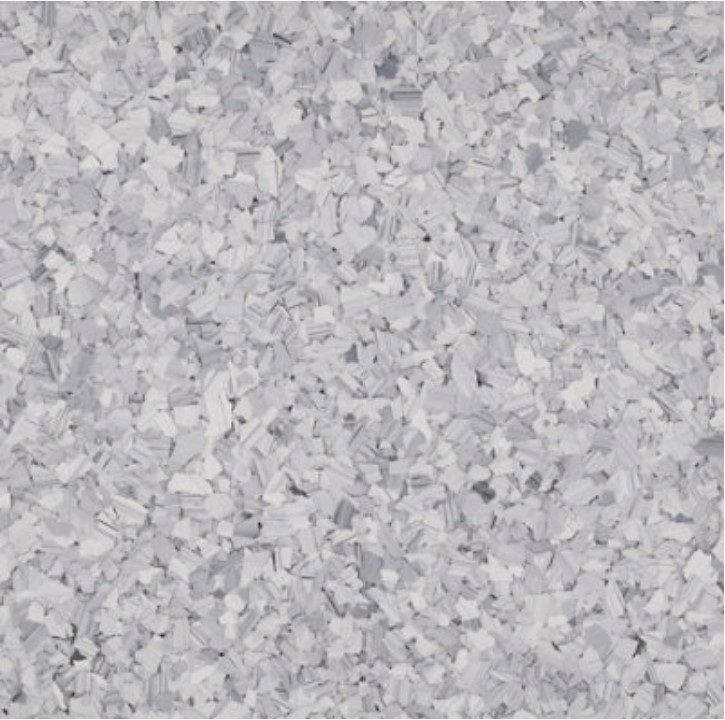

Liquid Granite or “Flake” Floor is also available in shimmering “Mica” chips.

Flake flooring still uses epoxy but with this option a broadcast medium is used to create depth, color and texture to give you a thicker more decorative appearance. These “flakes” come in dozens of traditional colors but they also come in neon, glow in the dark and shimmer (known as “Mica”)

Flake flooring still uses epoxy but with this option a broadcast medium is used to create depth, color and texture to give you a thicker more decorative appearance. These “flakes” come in dozens of traditional colors but they also come in neon, glow in the dark and shimmer (known as “Mica”)

The application process includes a primer coat of epoxy, then 1-2 broadcast coats of flake, mica or quartz and then a top coat of either epoxy or urethane. You can choose your colors from the chart below or visit our flake provider and create your own custom color.

This floor coating option has a slight texture to it and provides slip resistance while still enabling the user to clean the floors with ease.

Harborwalk Home

Dressed Up Stairwell

or check us out on Facebook

Choose from a wide array of color combinations.

Standard Blends:

Epoxy flake floors are a very popular decorative floor finish that are ideal for anybody wanting to give dull, dirty or damaged concrete in their home or business a new lease of life.

Getting a new flake epoxy floor will:

Cover dark, ugly stains and stop more from appearing.

Repair and cover cracks, chips, gouges and ugly spots.

Protect the concrete from water, chemicals and physical damage.

Brighten the entire space and add colour and reflectivity to your space.

Help avoid slips and falls through the option of textured finishes.

Installing any type of floor is never that easy and those videos you see on YouTube gloss over all the hard work that happens before you even touch a brush or roller.They dont cover product selection or heavy equipment used or the how and why of a hundred other little details that are extremely important for a successful installation. You dont have to worry about any of that. With experience int he coatings business since 1988 we’ve got you covered.

Like any type of floor covering, the surface underneath needs to be prepared properly for the result to look as good and last as long as it should. For epoxy flake floors, that means grinding the concrete with a dustless diamond grinder. While these types of machines are available for hire, getting one and figuring out how to use it is only one part of proper concrete preparation. You also must take care of other issues like concrete contamination, cracks, porosity and flatness, as well as transitions to other surfaces and fixtures.

There are not-so-obvious challenges when it comes time to apply too. Not many of those YouTube videos will ever talk about proper mixing practices, working times, pot life, dust control, weather conditions or any of the other nuances of the practice.